Electronic Ignition - CB72, CB77, CP77, CL72, CL77 |

Electronic Ignition: FAQ

|

|

|||||||||||||||||||

| This FAQ (Frequently Asked Questions) section applies to the Electronic Ignition Systems for the 1961 to 1968 Honda 247cc and 305cc Twins. | |||||||||||||||||||

|

|

|||||||||||||||||||

|

|

|||||||||||||||||||

|

Q.

A.

|

Can I leave the ignition in the "on" position with the motor not running? If yes, for how long? [ Applies to Kits produced before October, 2008 ] Yes. ...here is the full story: The heart and brain of the Electronic Ignition system is the control module, AKA the "black box" or "module." The black box, as any electronic device generates heat. This heat must be dissipated in order to maintain the control module within a safe operating temperature range. The Electronic Ignition kits, described here, dissipate the heat by radiating it through a heat sink mounted on top of the control module. On a moving bike, the airflow facilitates the exchange of heat between the heat sink and the atmosphere. On a stationary bike, with the ignition on and the motor not running, airflow is minimal and the amount of time the ignition can remain in the "on" position is limited. |

||||||||||||||||||

| The current installation instructions specify that the ignition should not be left in the "on" position, with the engine not running (power-on/engine-off), for more than one minute. Changes to the transistors, heat sink, and potting since the original development was completed have made the earlier one-minute limit somewhat conservative. With this in mind, and in response to several questions on this topic, new tests were run (March, 2003) to determine how long it would be safe to leave the ignition in the "on" state with the engine not running (power-on/engine-off). The new test values apply to the Electronic Ignition systems with the integral type of the module heat sink. If your control module's heat sink is attached with a screw, these modified values do not apply, however the early designs were superceded rather early on in the production and the new values, discussed here, apply to the majority of the units sold over the past several years, as well as to those currently in production. | |||||||||||||||||||

Please Note: In general, and regardless of whether your bike has the original points-type ignition or not, leaving the power on without starting the motor (power-on/engine-off) should be avoided, if only to reduce the chance of overheating the coils, and also to avoid the unnecessary battery drain. |

|||||||||||||||||||

| The control module's self-heating can be more than twice as high with the engine stopped as when it is running. Furthermore, how much self-heating occurs is strongly dependent on the ignition coil's primary resistance. A low resistance coil (typically, a high-performance aftermarket coil) will lead to a higher current draw and higher module temperatures. The typical range of coil primary resistance is from about 5 ohms down to about 3 ohms (the stock CB/CL 72/77 coils have about a 4.5 ohm primary resistance). | |||||||||||||||||||

|

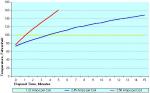

The attached graph shows the results of three different tests performed, on CB/CL 72/77 motors equipped with the Electronic Ignition upgrade kits. The values are graphed on a time vs. temperature chart: |

|||||||||||||||||||

|

|||||||||||||||||||

|

Yellow Line: [Stock Coils, Ignition "on" Motor "on"] The straight

yellow line shows the “baseline” steady-state temperature of

the module’s heat-sink fins in 70° F, still air, in the test

lab, with a load of 1.22 amperes per coil, after nearly three

hours of operation. This would be typical of a RUNNING Super Hawk

or Scrambler engine with stock coils (4.5 ohms) and the battery

at 14.5 volts (that is, being charged). |

|||||||||||||||||||

|

Blue Line: The blue line

shows the temperature rise of the module fins, over the course of

15 minutes, with a load of 2.45 amperes, per coil, starting at

about 73° F. The load of 2.45 amperes per coil would result from

having the ignition on with the engine not running, stock 4.5-ohm

Honda coils, and the battery terminal voltage at about 12.38

volts (as it would be under load, with the engine not running,

and therefore not charging). After 15 minutes, the fin

temperature reached 145° F, and the test was terminated. This

fin temperature, while just high enough to feel “hot” to a

prolonged touch of the hand, is still not hot enough to damage

the module, but it is getting there. From the look of the curve,

it appears that it would probably level off and stop getting any

hotter at around the 160° F to 165° F level (with the ambient

air at 70° F). While this would not damage the module, keep in

mind that the same test in Phoenix, AZ, in the summer, might

create fin temperatures exceeding 200° F, nearing the boiling

point of water; this would be too hot for reliability. In

summary: 15 minutes of module power-on with the engine stopped in

a cool ambient temperature would not be excessive, and 7 or 8

minutes in a hot ambient temperature would not be unreasonable,

using stock Honda 4.5 ohm coils. Note that one or both of the

coils will also be getting hot under these conditions, and they

may be less happy about the situation than the module, since

their power dissipation is 8 or 9 times as high. |

|||||||||||||||||||

|

Red Line: The graph’s

red line shows the module fin temperature over 5 minutes of

power-on/engine-off, with 3.5 amperes per coil - the equivalent of

a 12.38-volt battery terminal voltage and 3-ohm (high-performance)

ignition coils. In only 5 minutes, the high-current coils caused

the module fins to reach over 160° F, where the test was ended.

Note that the slope of the line was not even beginning to flatten

out at 5 minutes, indicating that the module would have gotten

very hot indeed. Again, if the module had started out at 115°F,

for example: in Phoenix, AZ, in the summer, it would have reached

about 200° F in only 1 or 2 minutes – again, too hot for

reliability. The module may survive one, or even a few trips to

that temperature, but then again, it may not. So, the rule for

low-resistance, high-performance coils is close to the original

conservative installation instructions guideline; 4 or 5 minutes

starting out near 70° F is permissible for power-on/engine-off

conditions in cool weather, and just 1 or 2 minutes in very

hot-weather conditions. |

|||||||||||||||||||

| In summary: try to avoid leaving the ignition "on" when the motor is "off" - this goes for any bike - and instead, turn both on and take the bike out for a nice ride! | |||||||||||||||||||

| CB-77 | CYP-77 | Road Test | Riding Log | Literature | Zen | Marketplace | VJ Survey | Links | Home |