Ground up: making a SuperHawk from scrapApologies for jumping in on your thread Dave but I'm worried by G-man's post as like you I've just rebuilt an engine using a ball race on the alternator side as the bearing surface on my crank originally fitted with the roller bearing was breaking up. I was able to obtain one of the Honda ball races I thought were suitable to deal with this problem but have cases with the oil feed for the later roller bearing. I was reassured by smbh's previous thread on this and lm's postings in that. I can't understand why the alternator side ball race should need a dedicated oil supply if the drive side ball race which is under more load manages without. Can anyone calm my troubled mind?

PhilD 1964 CB72

1964 CB77 Phil

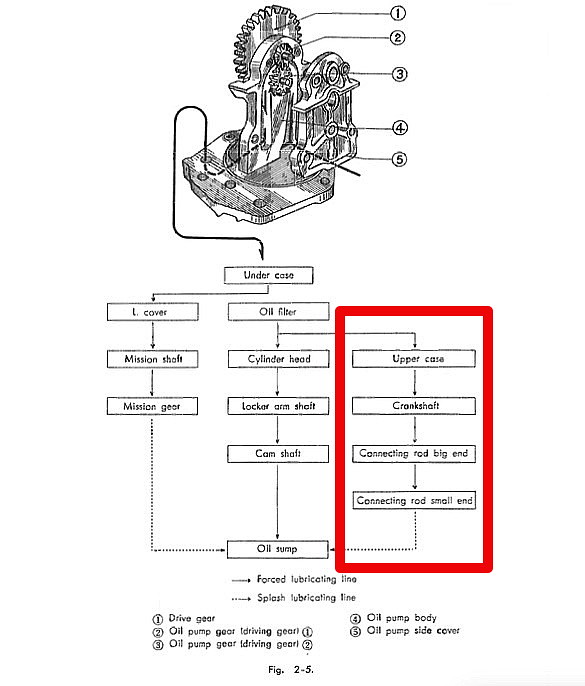

The primary side bearing - which was the one SMBH replaced with a sleeve is washed in oil from the primary case and crank case and is open both sides. The alternator side case has a dedicated feed (through holes in the case) which either lube the bearing directly (roller) or fed outboard of the bearing (ball race) but inboard the seal. The original ball-race has a shield on the crank side to keep the oil level up to around the level of that little cut out in the case. The area bounded by the inner shiels and the seal provides a reservior. SMBH got a NOS alternator side bearing from me and did the oilway mod. Yes a splash-fed bearing will work as people have done, but if you examine the oil-feed arrangements you will see that oil feed to that bearing, as Honda intended, is no longer happening once you block off its most important feed.... If you read the posts on crank rebuilding in my '61 CB72 thread I investigated how both that bearing and both big ends are positively fed. There are folks who think that these cranks are splash-fed with oil but it's much clever than that, and needs to be fro an engine of this performance. Of course - if you do as few miles as me, all of this probably doesn't matter. :-) All you need to do is to cut a small slot from the port that feeds the roller to just outside the ball race and you have oiling as Honda attended. This is what SMBH did.  G i

'60 C77 '60 C72 '62 C72 Dream '63 CL72

'61 CB72 '64 CB77 '65 CB160 '66 Matchless 350 '67 CL77 '67 S90 '77 CB400F Many thanks for the comprehensive reply G-man. I have of course read your very informative posts on crank rebuilding and oil pathways through these engines. I accept that the drive side ball race is open to both the crank case and the primary drive case though the bearing is above the oil level in the sump and must rely on splash lubrication albeit from both sides. The roller bearing for the alternator end of the crank is fully enclosed on both sides and obviously needs its dedicated oil feed. When I look at the engine however I can't see why a ball race at this site is any different from the ball race on the gear box main shaft which is of similar size and has a similar seal on its right and is at the same level in the cases with respect to the oil level. Although it turns at lower rpm than the crank it carries all the engine load and manages with splash oil feed. Afraid I am still puzzled and troubled.

PhilD 1964 CB72

1964 CB77 Phil

I don't suppose these engines are ever going to be used in anger like they were back in the day so you probably have nothing to worry about. I enjoy investigating how Honda tried to solve problems as they continued to develop these bikes and they clearly made a lot of revisions to the lubrication (and design) of the right side bearing. The left just changed diameter early on and that was it. The clutch and primary drive will churn up plenty of oil on the left side. Interestingly you cannot put a roller on the right side of early cranks as Honda did not harden the journal. Ball-race cranks have a radius at the crank web and (hardened) roller cranks have an undercut. As for the gearbox bearings, they run at much lower speed but the gears will throw plenty of oil around. I think that Honda were puzzled and troubled by this design as they were with the CB450. Eventually we got the CB250/350 which was a simpler/tidier design but uses exactly the same left hand crank bearing despite the primary drive being on the right! G

'60 C77 '60 C72 '62 C72 Dream '63 CL72

'61 CB72 '64 CB77 '65 CB160 '66 Matchless 350 '67 CL77 '67 S90 '77 CB400F Head workMoving on from the bottom end, I turned my attention to the piles of spare parts - here you can see the valve parts selection.

And the valve seat grinding - I know there is debate about whether or not to grind the exhaust valve seats due to special metallurgical work by Honda. In my case these were pitted with rust so there really was no choice.   I also made some Delrin (POM) rollers to replace the age-hardened neoprene parts on the cam and primary chain tensioners.  Re: Head workDave

A lot of progress.... It is the exhause valves that are hard faced and probably shouldn't be re-faced. The seats in the head are just part of the iron skull and can be re-machined. I will be interested to see your experience with the Delrin rollers. I have heard reports from others that the material comes loose on the steel bush. Please let us know how that works out as I think it is a good way to go. Enjoying your posts. G

'60 C77 '60 C72 '62 C72 Dream '63 CL72

'61 CB72 '64 CB77 '65 CB160 '66 Matchless 350 '67 CL77 '67 S90 '77 CB400F Got it together, now a questionHi everyone,

Jumping ahead a bit here, but I've got the thing pretty much fully assembled, wired, oiled and fueled. Maybe later I'll tell you about my wheel drama, trying unsuccessfully to make exhaust headers, and various other steps along a crooked path. I'm having a strange problem with ignition timing. I set the static timing and that seems to be right on. The bike starts and idles well. The problem comes when I try to give it throttle - it almost looks like the timing advance mechanism is working in reverse. It stumbles and eventually fouls the plugs if I try to open the throttle at all. Wondering if anyone has a clue - could there be something assembled backward? My next move is new points and condenser. After that I'm thinking I'll have to pull the engine so I can open up the top end and confirm the advance mechanism is assembled properly.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||