Posted: Tue Sep 29, 2015 8:18 am

Those polished hubs are going to look real nice. Did the early bikes come that way?

S

S

Vintage Honda Owners, Restorers, Riders and Admirers

https://www.honda305.com/forum/

Steverino wrote:Those polished hubs are going to look real nice. Did the early bikes come that way?

S

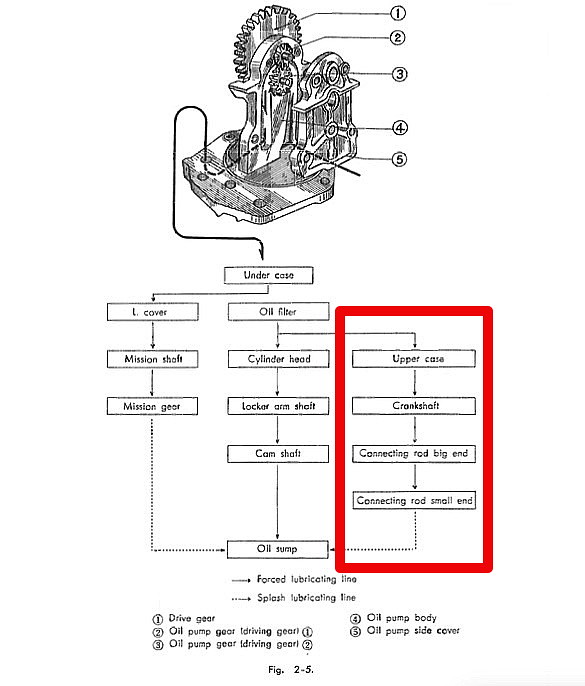

G-Man wrote:I got the eBay 'spare' crank back together yesterday and had to sort out some decent rods for it after the originals were unusable.

It's interesting how many variations -both OEM and aftermarket - there are. On the right here is a pattern rod which has not got the oil slots made properly. The '12 O'clock" position should have a complete slot which squirts escaping oil from the big-end up toward the piston and small end, like the one on the left.

squirts escaping oil from the big-end up toward the piston and small end

G-Man wrote:LM - Good questions.

Although the centre main bearings are indeed fed from oil descending from above, they also have a direct feed from the oil gallery at the front of the engine, getting fresh oil straight from the filter before it gets to the top of the engine. The main bearings are internally ported to direct oil sideways in to a pair of 'oil slingers" (centrifuges) which feed oil into a gallery in the centre of each big end. The hole you can see at around 10 O'clock is the hole into the hollow big-end pin. I have removed the aluminum plug at the outer end to clean the gallery.

As this rotates, oil is flung outwards, boosting the pressure feed to the big end, via two oilways in the big end pin. Just like you swung a bucket of water over your head as a kid, and it didn't run out, the oil is 'forced' into the big end bearing. The pressure (force generated on the oil) depends on the diameter of the annular gallery in the flywheel and the rotational speed of the engine.

F = 'mass' x 'radius of centrifuge' x 'rotational speed squared'

More speed equates to more pressure at the bearing providing we don't let the oil escape too quickly and providing we can get enough in via the main bearing oil feed. Doubling the speed increases the pressure by four times. These galleries also work as a centrifugal oil filter, collecting sludge, as the 'mass' of dirt particles will normally be greater than the oil around it. The hardness of this sludge and the way it gets packed in is a testament to the forces generated in that centrufugal oil slinger slot.