Electronic Ignition - CB72, CB77, CP77, CL72, CL77 |

|

|

|

honda305 Forum | h305 Survey | h305 Marketplace | h305 Mailing List | h305 Auctions |

e-Ignition - Development

|

Vintage Racers | Motorcycles For Sale | Design | Featured Parts | NOS Parts | Classified Ads |

|

|

- Introduction - Page 1, Page 2

- Technical Detail - Page 3

For a complete picture, take a look at the other pertinent sections:

Continued from Page 1

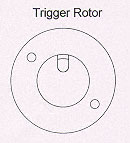

About the first thing I found out, because Bill was knowledgeable enough and persistent enough to educate me, was that adapting my existing ignition system, with built-in electronic advance, to the Superhawk was a little bit futile, for two reasons. First, most Superhawk owners were not going to be willing to drop the motor and pull off the camshaft cover, then go in and disable the centrifugal advance mechanism, then put it all back together again, just to see how they liked this new ignition system. Second, there was no simple and obvious way to mechanically pick up the "fixed" part of the hollow right-side camshaft half itself – it being largely buried behind the points housing. (The significance here is that the trigger rotor on an electronically-advanced system has to be fixed in angle relative to the camshaft, so the rotor can’t mount to the existing points cam unless the advance mechanism is "locked".) Against all my previous experience of designing the more-complex electronically-advanced ignition, the best solution for the Superhawk seemed to be to retain the original centrifugal advance and add pointless switching. So, we all have Bill to thank for getting me past my engineering myopia on this point.

Getting to the final system was a three-part job. First, I designed up and had machined a prototype of the small aluminum rotor that mounts over the existing points cam and carries the magnets that trigger (and un-trigger – the spacing between these two events determines the dwell angle) the Hall-Effect sensors that signal when it’s time to spark. At the same time, I designed and had fabricated the fiberglass-backed printed-circuit board (PCB) that replaces the original points backing plate and carries the Hall-Effect sensors. Finally, I hand-build a control box containing the power transistors that actually turn the coil current on and off, using point-to-point wiring inside a commercial die-cast housing. We went through a little fiddling with this setup and got it working, and Bill proceeded to put some test miles on the bike.

Next, I designed and built a batch of printed-circuit boards to replace the hand-wired control box. Again, after a little more fiddling, we had this version working. This first PCB used through-hole parts (the kind of electronic parts that have wire leads on them that you poke through the solder-plated holes of the PCB, and then solder them in place). At about 3" by 2.5" by 1" thick, the PCB version was roughly 2/3 the size of the hand-wired prototype, and I thought I was happy – for a while.

While the Superhawk system was evolving, the XS-650 ignition system grew up to be pretty complicated, and while it worked just like I wanted it to, I was unhappy about its size, about 6" by 3" by 1" deep. While that’s no worse than a lot of OEM "black boxes," it’s still always hard to find somewhere on (or in) a motorcycle chassis to mount a clunky rectangular thing with a connector and wires coming out of it. After chewing this problem over for a while, I decided to bite the bullet, and redesigned the whole circuit to use surface-mount electronic parts. These parts are really tiny – half the size of their conventional wire-leaded, through-hole counterparts. The redesign effort resulted in an acceptably tidy package for the XS-650 ignition – but now the Superhawk ignition’s control box looked kind of bulky in comparison.

The last step in the Superhawk ignition saga was to use the same surface-mount technology to design a brand-new, smaller control-box PCB for the Superhawk that could be mounted into a really tiny box and potted with epoxy to make it water-resistant and vibration-proof. This last change resulted in a control box 2.3" by 1.7" by 0.9", including a finned aluminum heat-sink to assist in cooling the smaller, tighter package. At this size and weight, there are a lot more inviting places to mount the box, as illustrated in Michael Stoic’s nearby chronicle of the installation he performed on his own bike.

***

That’s the story behind the Superhawk ignition system. For installation details and other pertinent information, follow the links below...

|

|

h305: Forum |

|||

| CB-77 | CYP-77 | Road Test | Riding Log | Literature | Zen | Marketplace | VJ Survey | Links | Home | |||