Electronic Ignition - CB72, CB77, CP77, CL72, CL77 |

|

|

|

honda305 Forum | h305 Survey | h305 Marketplace | h305 Mailing List | h305 Auctions |

e-Ignition - Development

|

Vintage Racers | Motorcycles For Sale | Design | Featured Parts | NOS Parts | Classified Ads |

|

|

- Introduction - Page 1, Page 2

- Technical Detail - Page 3

For a complete picture, take a look at the other pertinent sections:

For a little technical detail, here’s how the system works in general terms:

The two Hall-Effect sensors, one for the left-hand cylinder and one for the right-hand cylinder, are mounted on the pickup plate PCB that fits where the points backing plate originally mounted. Like the points backing plate, the pickup plate’s mounting holes are slotted to allow rotation for ignition timing adjustment. The two sensors are located exactly 90° apart in angle, which of course equates to 180° of crankshaft rotation between the two firing events (for the CB/CL Type 1 engines). The Hall-Effect sensors don’t fire the ignition coils directly – they can only handle a few milliamperes of current, and the coils draw a few amperes. Instead, the Hall-Effect sensors send a signal to the control box, which houses a pair of independent high-voltage power transistors, one for each cylinder. These transistors switch the coil current, under the timing direction of the Hall-Effect sensors. The transistors are rated to handle the inductive kick-back created by the coils when they fire. This is the same kick-back that would ruin mechanical contact points very quickly with arcing if the condensers (capacitors) of the original setup were not there to absorb the energy. Leaving the condensers out of the circuit when rugged modern transistors are employed helps make a stronger spark, since the condensers are not there to rob a little of the spark energy each time the plug fires.

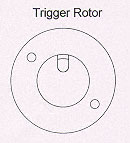

The rotor on the end of the camshaft carries two magnets, located 180° apart on the rotor. One magnet causes the Hall-Effect sensor to "tell" its corresponding power transistor to cut off the coil current, causing the magnetic field in the coil to collapse and inducing a high-voltage surge in the secondary winding, creating a spark at the plug. The second magnet tells the Hall-Effect sensor to start the current flowing through the coil again, building the magnetic field in the coil back up and preparing it to create the next spark. The "dwell" angle is the amount of crankshaft rotation (in degrees of angle) during which coil current is flowing. Since it takes a while for the magnetic field in the coil to build up to its maximum level ("coil saturation"), a good goal is to have the dwell angle occupy enough time to fully saturate the coil, even at high engine speeds. With the rotor magnets situated at 180° on the cam, the crank rotation during dwell is 360° for each cylinder. Even wound up to 12,000 RPM ("Kids, don’t try this at home, this is for professional racers on a closed course……"), a 360° (at the crankshaft) dwell angle corresponds to 5 milliseconds, which is long enough for most all ignition coils to reach over 90% of their maximum energy storage. This dwell time is substantially longer than that delivered by the mechanical breaker-points setup. Especially in the upper 2/3 of the rev range, the longer dwell and resulting higher spark energy is responsible for snappier engine performance, even with stock coils.

For those interested in ultimate performance, the solid-state ignition system is designed to handle high-energy aftermarket coils, down to about 3 ohms of primary resistance. 3-ohm coils shouldn’t be used with breaker points, because the higher primary current fries the contacts in short order - a 4.5 to 5 ohm coil is the common lower limit for a points system. While the difference may not seem large, a 3-ohm coil draws 50% more current, all things being equal, than a 4.5-ohm coil, and more current generally equates to more spark energy.

***

That’s the story behind the Superhawk ignition system. For installation details and other pertinent information, follow the links below...

|

|

h305: Forum |

|||

| CB-77 | CYP-77 | Road Test | Riding Log | Literature | Zen | Marketplace | VJ Survey | Links | Home | |||